01/ Product

The project covered two product groups included in the OPTITERM brand offer. These are heat exchangers (constituting the dominant product range) and water reservoirs equipped with heating coils that allow to heat the water. These are specialized devices of a very technical nature, which are part of heating installations.

02/ Scope of work

The design of devices with the determination of the principles for designing future products, colours, list of materials, finishing of the detail, design of elements product identification, method of marking, labels, principles of designing packaging for devices, design of cartons, methods of packaging wrapping, exhibition exposition, showroom – all this has been included in the book of product design standards.

03/ Assumptions

The OPTITERM offer is targeted to an individual customer, who – apart from the offered functionality – increasingly also cares for the appearance of the product, i.e. its form and shape. Taking these features as a priority of our activities, we have created coherent sets of devices for our customer.

Heat exchangers

The heat exchangers offered by the OPTITERM brand are devices manufactured in the JAD technology, also called shell and tube heat exchangers. This means that the heat exchange occurs in a system of tubes enclosed in a metal casing (jacket).

Exchangers come in many sizes, but the principle of their construction is the same for all of them. The technology largely determines the appearance of the device itself. However, there are also possible actions that could increase the visual attractiveness of products. These include: consistent use of the adopted colours, marking and the use of dedicated labels, as well as additional elements such as terminating plugs.

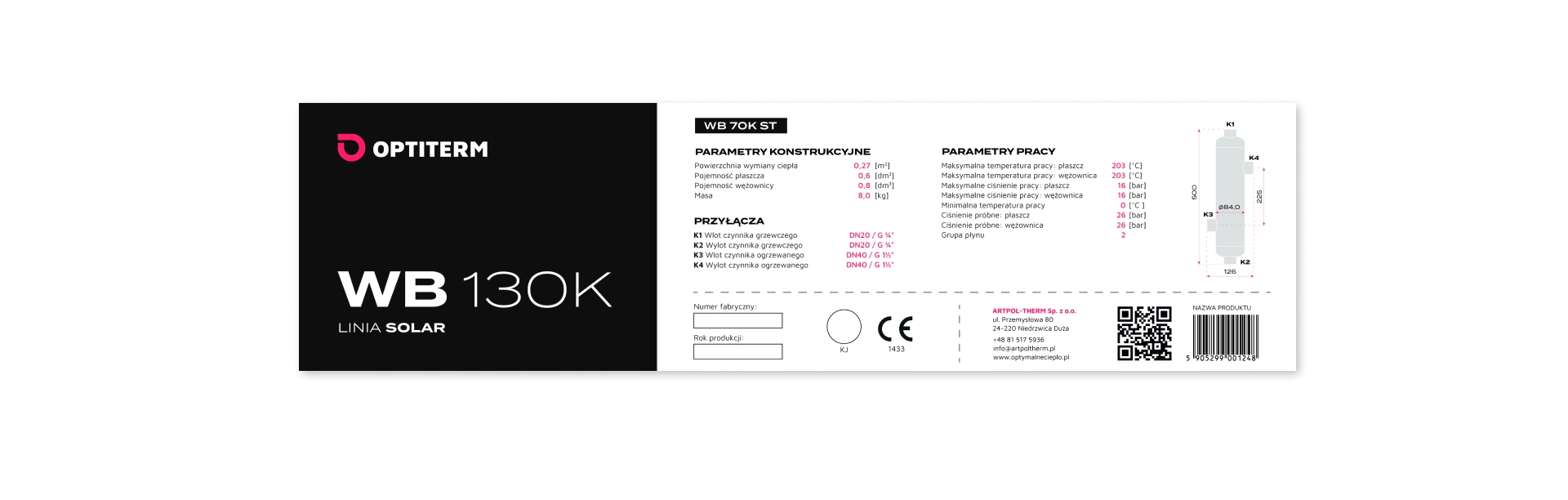

Labels

Exchangers come in many sizes, but the principle of their construction is the same for all of them. The technology largely determines the appearance of the device itself. However, there are also possible actions that could increase the visual attractiveness of products. These include: consistent use of the adopted colours, marking and the use of dedicated labels, as well as additional elements such as terminating plugs.

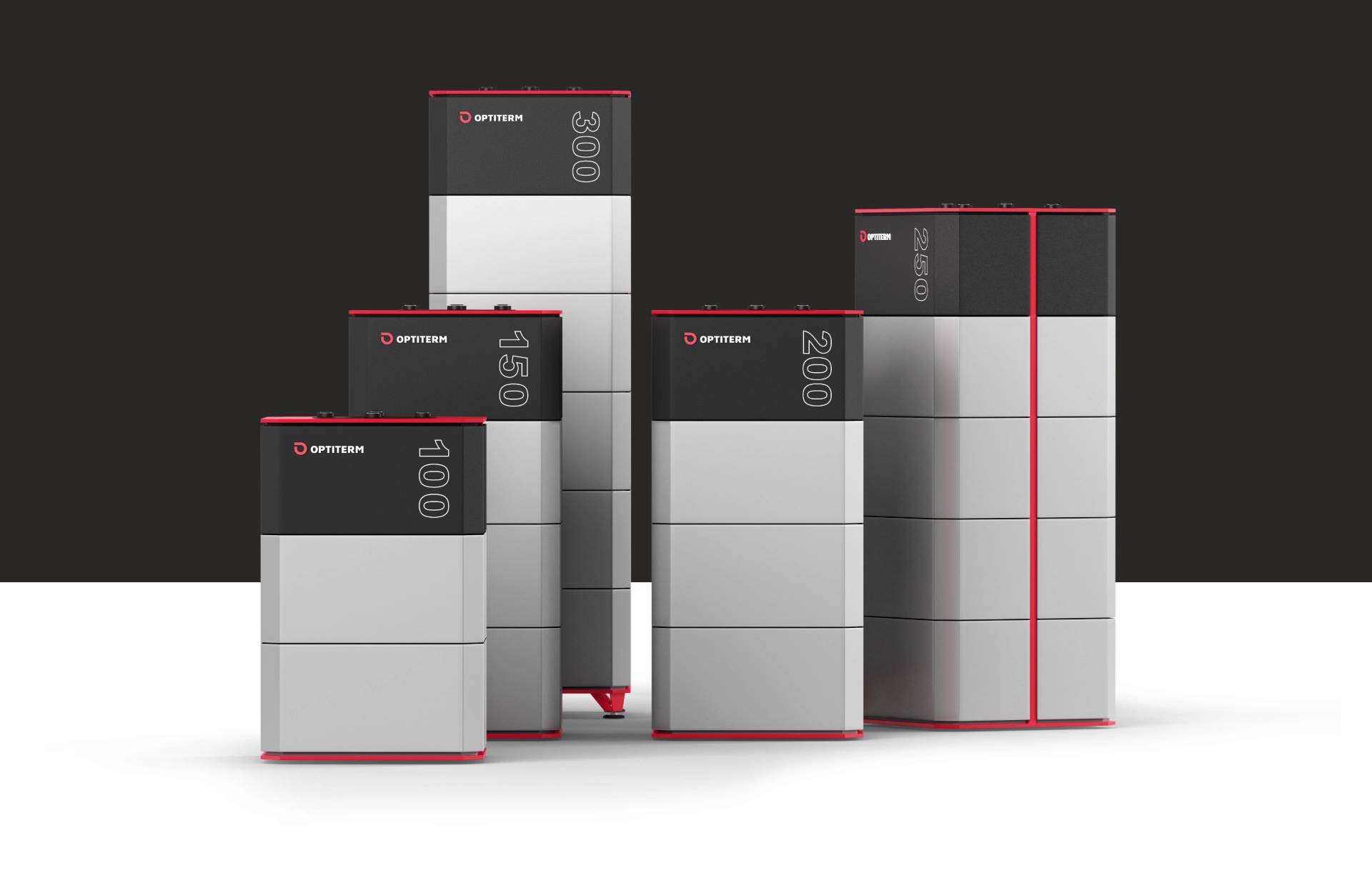

Water tanks

Water tanks are the second group of devices manufactured under the OPTITERM brand. OPTITERM tanks are intended for individual customers. They are manufactured in five different capacities: 100, 150, 200, 250 and 300 litres. The equipment tanks can be equipped with coils, and the whole is insulated and enclosed in a modular housing.

The appearance of the devices is a direct result of the applied design solutions (especially the modular structure of the housing) and the method of communication of OPTITERM products, the main part of which is the visual identification system developed for this brand.

The basic design principle is the consistent use of the adopted colour scheme for the entire range of devices. Tank enclosures, regardless of their capacity, consist of identical, repetitive elements forming characteristic strips. The highest strip is the surface intended for marking the device, hence its different colour and surface structure. The combination of a light, steel body, with the graphite upper strip and additives in red create a coherent appearance of all water tanks offered by OPTITERM.

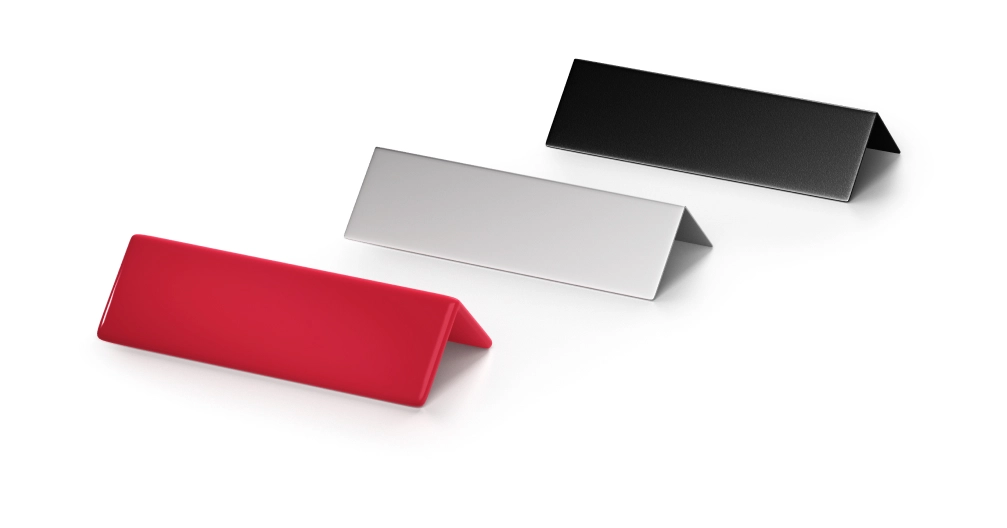

Colour schemes

The colour of steel is the dominant colour in the case of water tanks, in which most of the housing is made of stainless steel sheet. In the case of heat exchangers, however, several equivalent colour solutions can be applied.

Red is used both as a complementary colour and for accentuating selected batches of devices. In the case of heat exchangers, it is used in plastic terminating plugs of nozzles.

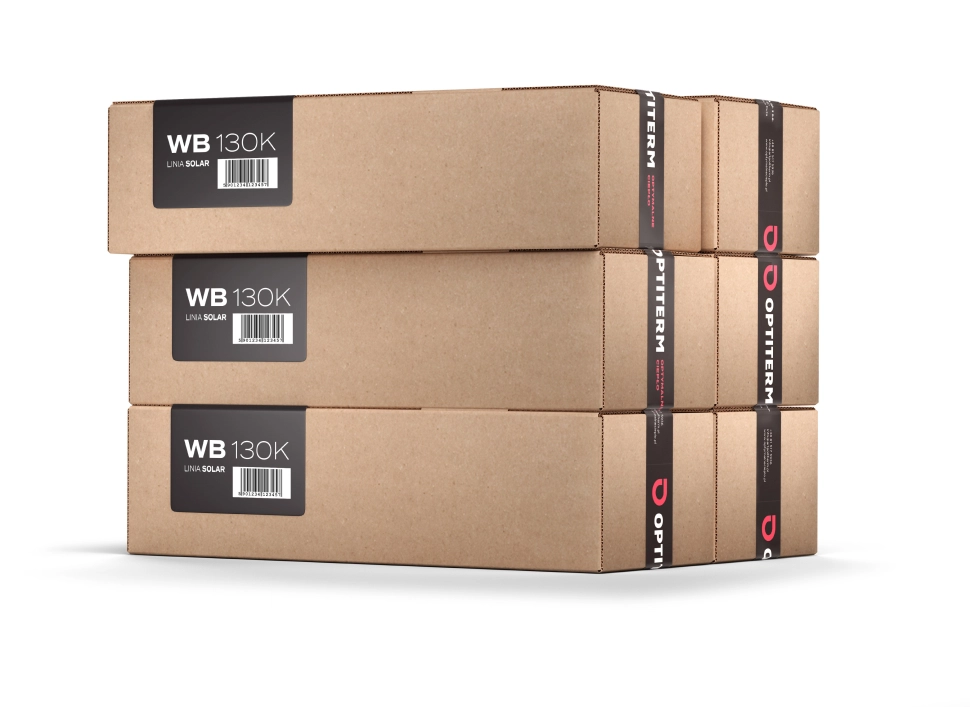

OPTITERM products are mostly massive devices requiring good protection for transport. The basic role of packaging is to protect the product itself, which does not mean that the aesthetic sphere is completely irrelevant here.

Due to their specific design heat exchangers are most often transported in dedicated, wooden crates. Such crates should be marked at least with the signage in form of the OPTITERM graphic mark, and in the case of additional packaging in a carton, the packaging should be secured with a specially designed packaging tape.

For information purposes, a label should also be affixed to the packaging containing at least the manufacturer’s logo and the name (code) of the device.

The label should also include the barcode assigned to the product.

OPTITERM devices can also be wrapped in protective bubble wrap, stretch film and transported directly on euro pallets.

This mode of transport will most often concern water tanks, which are heavier and larger devices than heat exchangers.

In this case, the use of packing tapes can be an excellent solution to solve the issue of appropriate protection while clearly marking products with the OPTITERM brand.

2020 / 2021

project management: Radosław Nowakowski

support: Patryk Góźdź

project coordinator: Aneta Biszek

designers: Radosław Nowakowski, Natalia Konowałek

3D visualizations: Radosław Nowakowski